An extremely thin sheet of pure aluminum laminated onto each side of an aluminum alloy sheet improves the corrosion resistance with little impairment of strength.

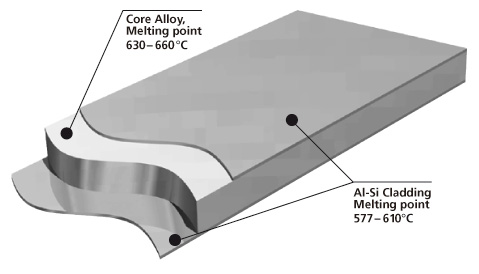

Clad sheet aluminum alloy.

This thin layer usually makes up 5 to 10 of the total thickness of the brazing sheet.

Cladding in general is the application of one type of substance or material over a different material effectively creating a protective layer on the underlying material.

The trade name of this aluminum laminate as originated by the aluminum company of america is alcad.

Aluminum cladding is cladding that is created using a thin coating of aluminum on the exterior of the product.

The trade name of this aluminum laminate as originated by the aluminum company of america is alcad.

From this trade name the adjective clad and the verb cladding have been derived.

From this trade name the adjective clad and the verb cladding have been derived.

Aluminum cladding sheet 1060 3003 is available in smooth stucco embossed with or without moisture barrier craft paper and poly surlyn.

It melts and flows during the brazing process to provide upon cooling a metallic bond between the components.

Alclad is a trademark of alcoa but the term is also used generically.

0 05 0 1mm ultra thin h65 h90 t2 aluminium clad sheet 5 series 6 series for cable lightweight copper clad aluminum sheet with high electrical conductivity high strength copper clad aluminum plate with good heat dissipation.

Aluminium cladding for pipe insulation is typically manufactured using alloys aa 3003 3105 1050 1060 1070 5052 5005.

Brazing sheet comprises of a core alloy clad on 1 or 2 sides with a lower melting aluminum silicon al si alloy.

An extremely thin sheet of pure aluminum laminated onto each side of an aluminum alloy sheet improves the corrosion resistance with little impairment of strength.

It has a melting point of about 500 degrees celsius or 932 degrees fahrenheit.